Our

Our technical teams specialise in scalable, cost-driven manufacture of drug delivery devices, specifically for potent API applications. We employ moulding, solvent casting, extrusion and co-extrusion processes, that are developed in our R&D labs, proven in our pilot GMP suites and scaled in our GMP manufacturing facility.

Formulation

and Processing

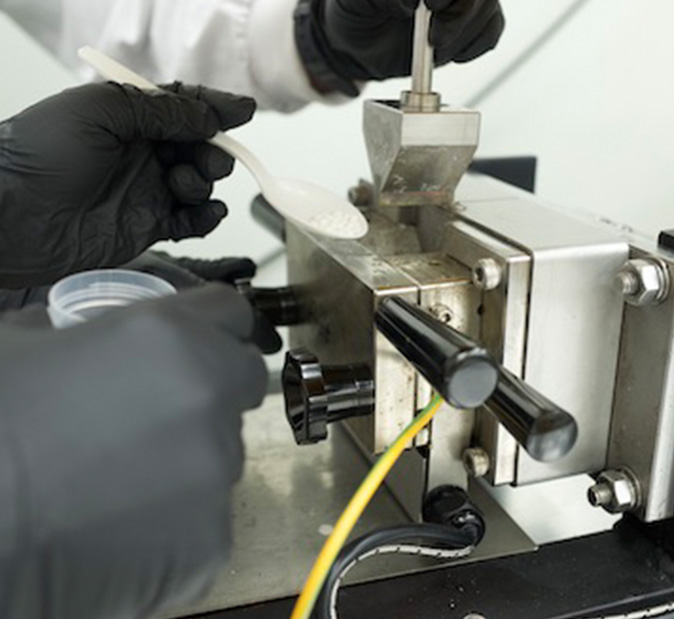

- Compounding (polymer/drug composite manufacture)

- Batch mixing (30-50g scale)

- Twin-screw extrusion (>500g scale)

- Extrusion

- Twin-screw extrusion (rod profiles)

- Twin-screw co-extrusion (encapsulated rod profiles)

- Moulding

- Injection moulding

- Compression moulding

- Silicone and thermoplastic applications

Development

and Manufacture

- DoE screening of moulded formulations

- Process development

- Analytical development

- Pilot-scale GMP manufacture (up to 50kg batch scale)

- Industrial-scale GMP manufacture (up to 600kg batch scale)

- Packaging

- Labelling

- Large GMP warehouse

Analytics

- R&D (flexible) and GLP (controlled) Quality teams

- Raw material, in-process and release testing

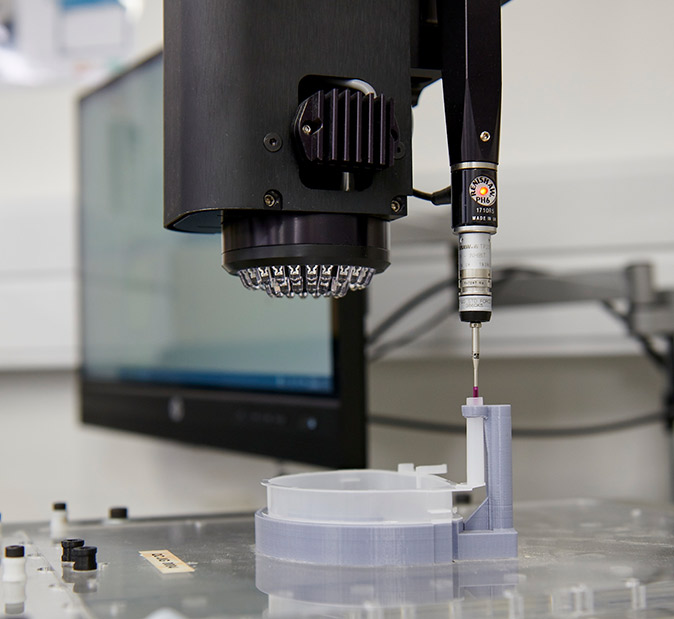

- Image-based, automated QC measurement (Micro-Vu)

- HPLC, UPLC, UV-Vis, FTIR, (chromatography/spectral analysis)

- DSC (thermal analysis)

- Polarised microscopy (materials and crystallisation analysis)

- Dissolution with autosampling (drug release)

- Sonication or soxhlet (content analysis)

- Mechanical testing

- Stability (intermediate and accelerated chambers)

Quality

- GMP (pharmaceutical)

- FDA registered (currently supplying to >50 countries worldwide)

- NIR in-process control

- Quality by Design (QbD)

- Dedicated Quality Control team

- Dedicated Quality Assurance team

- Equipment Qualification (IQ, OQ, PQ)

- Process validation (process studies, gauge R&R, method validation)

- Tool inspections and refurbishment

- Root cause analysis (RCA, FMEA)